DK energry original and professonal solar materials for solar pv modules

Solar Photovoltaic(pv) power generation technology is a technology that directly converts solar energy into electrical energy. The photovoltaic power generation system has many advantages of safety and reliability, no noise, low pollution, no fuel consumption and short construction period.

According to statistics, by 2021, the total installed capacity of solar photovoltaic(pv) power generation in the world will reach 920GW; the newly installed capacity will reach 170GW, a year-on-year increase of 30.8%.

Under the guidance of carbon neutrality goals, solar photovoltaic power generation will usher in rapid development opportunities. It is estimated that the global photovoltaic installed capacity will increase from 170GW in 2021 to 270-330GW in 2025.

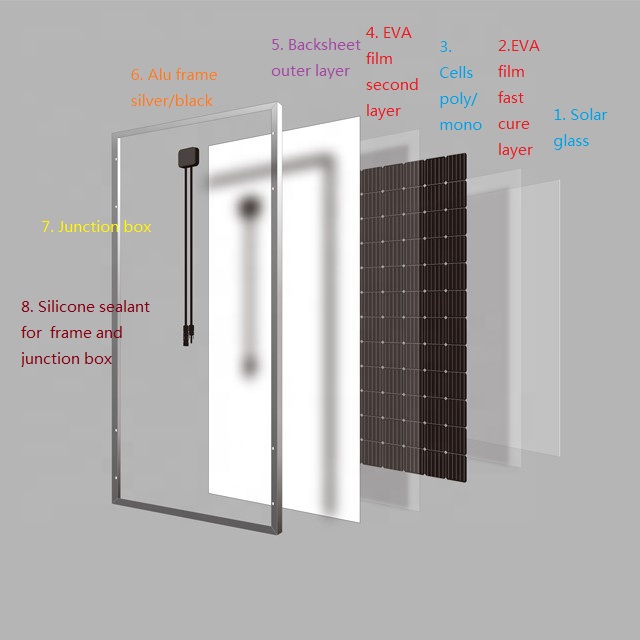

According to statistics, in 2021, the cumulative installed capacity of photovoltaics in my country ranks first in the world for 7 consecutive years, and the newly installed photovoltaic capacity ranks first in the world for 9 consecutive years. The newly installed capacity is 54.88GW, and the cumulative installed capacity reaches 308GW. In 2021, my country's photovoltaic power generation will be 325.9 billion kWh, accounting for 3.9% of the country's total power generation. The service life of crystalline silicon photovoltaic modules is generally 20 to 25 years. Due to the influence of various natural factors such as wind, sun, rain, etc. outdoors, the service life of modules that are put into operation is generally less than 20 years, and will be scrapped or retired in advance. The structural composition of crystalline silicon photovoltaic modules includes aluminum frame, solar junction box, solar tempered glass, crystalline silicon cells, backsheet and EVA film. EVA encapsulation film layer adhesion.

The structure and composition of crystalline silicon photovoltaic modules are shown in Figure 1.

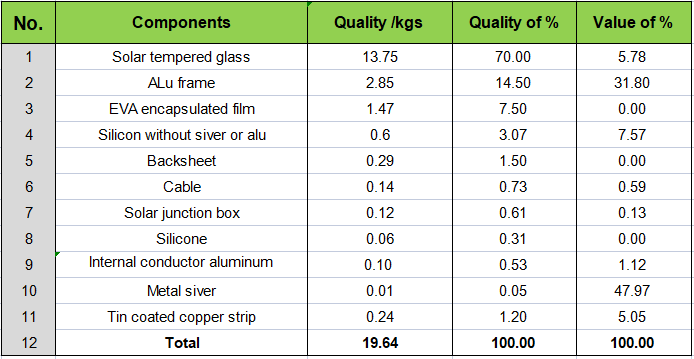

The distribution ratio and value of each component in crystalline silicon photovoltaic modules are shown in Table 1 (taking 60-piece crystalline silicon photovoltaic modules as an example).

Figure 1 Schematic diagram of the structure and composition of crystalline silicon photovoltaic modules

Table 1 Distribution ratio and value ratio of each component in 60-chip crystalline silicon photovoltaic modules

From Table 1, it can be seen that the proportion of each component in the crystalline silicon photovoltaic module structure is ranked from high to low: tempered glass >aluminum frame > EVA film > silicone wafer > backsheet > tin-coated copper strip> cable >solar junction box >inner conductor aluminum >silicone>metallic silver. The value proportion of each component in the photovoltaic module is ranked from high to low: metal silver >aluminum frame>silicon wafer > solar tempered glass > tin-coated copper strip> inner conductor aluminum > cable > solar junction box.

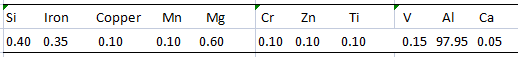

The aluminum alloy frame is a commonly used metal frame. Its function is to protect the crystalline silicon photovoltaic module, improve the overall mechanical strength of the module, and facilitate the transportation and installation of the module. It is bonded to the module with silica gel. The aluminum alloy frame is generally made of internationally accepted 6063T6 aluminum alloy material, and the surface of the aluminum alloy frame is usually oxidized. The specific components are shown in Table 2.

Table 2 Composition of aluminum alloy frame materials (mass fraction)/%

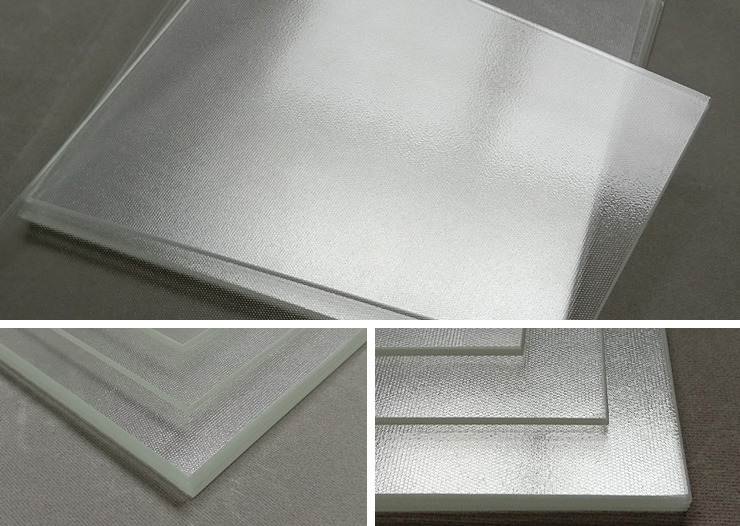

Tempered glass has the advantages of high strength, high light transmittance, good mechanical properties, long service life and stable chemical properties. The anti-reflection coating applied on the glass surface can effectively reduce the reflectivity of tempered glass.

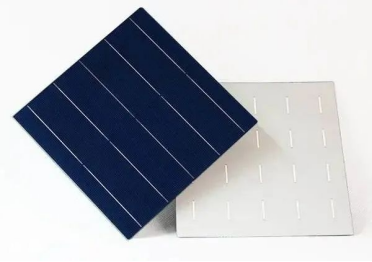

•Crystalline silicon cells

Crystalline silicon cells are divided into monocrystalline silicon cells and polycrystalline silicon cells. The conversion efficiency of monocrystalline silicon solar cells can reach about 22%; the conversion efficiency of polycrystalline silicon solar cells is slightly lower than that of monocrystalline silicon, and the production cost is relatively low.

The back sheet plays the role of reflecting sunlight, protecting silicon wafer cells, insulating, sealing and moisture-proof in photovoltaic modules, and has functions such as improving infrared reflection efficiency, reducing module operating temperature and improving module working efficiency. At present, the back sheet material of solar cells is mainly TPT fluorine-containing back sheet.

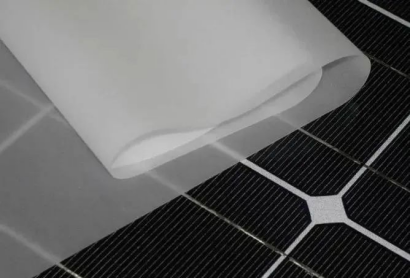

Nearly 80% of photovoltaic modules use EVA (full name ethylene-vinyl acetate copolymer) as the encapsulation material. EVA has the characteristics of shock resistance, moisture resistance, heat insulation, non-toxicity, good flexibility, high light transmittance, corrosion resistance, strong fusion bonding and no water absorption. It is not only cheap, but also works well with fillers and colorants. Compatible, is a very suitable packaging material for solar cells.

DK energy company can help you find the original solar materials in various solar glass, pv ribbon, EVA film, Silicone sealant , Solar junction ,Back sheet and alumium frame for solar panels pv cells componets. Welcome to your visit!