The difference and application of Integrated and Split Photovoltaic Junction Boxes in the PV Industry

In the backdrop of the surging global demand for clean energy, the photovoltaic (PV) industry, as a cornerstone of sustainable energy development, is witnessing rapid technological innovation and market expansion. The photovoltaic junction box, a crucial device for circuit connection and system protection in PV modules, has its technological evolution playing a significant role in enhancing the efficiency and stability of PV systems. Currently, integrated and split photovoltaic junction boxes coexist in the market, showing distinct differences in structure, performance, and application scenarios.

I. Integrated Photovoltaic Junction Boxes

A. Structural and Compositional Features:

Integrated junction boxes typically house one or more diodes along with positive and negative cables within a single enclosure. Generally, only one such junction box is required for a single PV module. This design results in a relatively simple structure, which simplifies the installation process. For instance, in the manufacturing of traditional PV modules, the integrated junction box can be directly attached to the back of the module during the production line assembly, reducing the complexity of the connection process.

B. Performance Characteristics:

1. Cost - effectiveness: Due to its simple structure and fewer components, the integrated junction box often comes with a lower production cost. This cost - advantage makes it an attractive option for PV module manufacturers aiming to keep production costs down, especially in large - scale production scenarios.

2. Installation Convenience: With a single - box design, the installation of integrated junction boxes is straightforward. Installers only need to make connections at a single point on the PV module, which is highly beneficial for small - scale and medium - scale PV power generation projects where installation speed and simplicity are valued. For example, in rooftop PV installations on residential buildings, the ease of installing integrated junction boxes can significantly shorten the installation time.

3. Limitations in Heat Dissipation and Electrical Performance: However, as PV modules are evolving towards higher power and larger current outputs, integrated junction boxes face challenges. When multiple diodes are concentrated in one box, the heat generated during operation is difficult to dissipate effectively. High temperatures can not only reduce the efficiency of the diodes but also shorten their lifespan. Additionally, the internal resistance of the integrated junction box may increase due to the complex internal electrical connections, leading to power losses in the PV system.

II. Split Photovoltaic Junction Boxes

A. Structural and Compositional Features

Split - type junction boxes are composed of multiple smaller boxes. Each box usually contains only one diode, and the positive and negative cables are distributed among different boxes. For a single PV module, at least two such boxes are required. This design is a departure from the traditional integrated structure, aiming to address the limitations of the latter.

B. Performance Characteristics

1. Superior Heat Dissipation: The most prominent advantage of split - type junction boxes is their excellent heat dissipation performance. Since each diode is placed in an independent box, the heat generated by the diode can be dissipated more effectively. This helps to maintain a lower operating temperature for the diodes, improving their performance and extending their service life. In large - scale ground - mounted PV power plants, where high - power PV modules are used, the efficient heat dissipation of split - type junction boxes can ensure the stable operation of the entire PV system.

2. Enhanced Electrical Performance: By simplifying the connection of busbars inside the PV module, split - type junction boxes can reduce the overall loop resistance of the module. This results in an increase in the output power of the PV module. For example, in some advanced PV module designs, such as half - cell and double - glass modules, split - type junction boxes have been proven to improve the conversion efficiency of the modules.

3. Cost and Installation Complexity: On the downside, the increase in the number of boxes in split - type junction boxes may lead to a higher overall cost compared to integrated ones. Moreover, the installation process is more complex as installers need to handle multiple boxes and ensure the correct connection between them. This requires more skilled labor and higher installation precision.

III. Application Scenarios

A. Integrated Junction Boxes

1. Residential Rooftop PV Systems: Integrated junction boxes are well - suited for residential rooftop PV systems. These systems usually have a relatively small scale, and the simplicity and low cost of integrated junction boxes are highly valued. Homeowners and installers can complete the installation quickly and at a lower cost, making solar energy more accessible to ordinary households.

2. Small - scale Distributed PV Projects: In small - scale distributed PV projects, such as small - scale commercial rooftops or off - grid PV systems with limited power requirements, integrated junction boxes can meet the basic needs of power connection and protection. Their easy - to - install feature is also beneficial for projects with tight installation schedules.

B. Split Junction Boxes

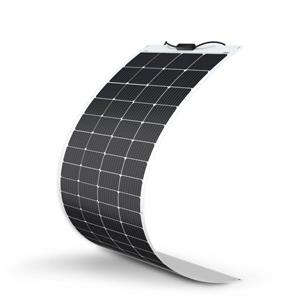

1. Large - scale Ground - mounted PV Power Plants: In large - scale ground - mounted PV power plants, where high - power PV modules are widely used, the superior heat dissipation and electrical performance of split - type junction boxes are crucial. These power plants require high - efficiency and stable operation of PV systems to ensure a high return on investment. Split - type junction boxes can better meet these requirements, reducing the risk of system failures caused by overheating and improving the overall power generation efficiency.

2. Advanced PV Module Applications: For advanced PV module designs, such as double - glass modules and half - cell modules, split - type junction boxes are often the preferred choice. These modules usually have higher power outputs and more complex internal structures, and split - type junction boxes can better adapt to these characteristics, maximizing the performance advantages of the modules.

In conclusion, both integrated and split photovoltaic junction boxes have their own characteristics and application scopes in the PV industry. As the PV technology continues to develop, manufacturers are constantly innovating to improve the performance and cost - effectiveness of junction boxes. Whether it is to simplify the installation process of integrated junction boxes or to optimize the cost - performance ratio of split - type junction boxes, the ultimate goal is to promote the wider application and development of the PV industry and contribute to the global clean energy transition.