-

1004-2025

Flexible Solar Panels: Redefining the Future of Renewable Energy.

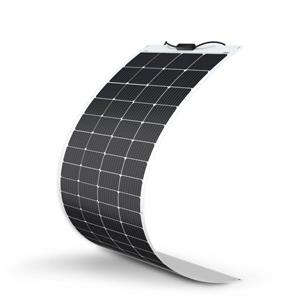

By 2025, the development of flexible photovoltaic technology will focus on three core breakthrough directions: In the materials field, efforts will concentrate on improving the environmental stability of perovskite components and developing lead-free processes, while also exploring new quantum dot composite structures to enhance photoelectric conversion efficiency. In terms of manufacturing processes, advancements will be made in intelligent roll-to-roll precision printing technology and multi-material layer integration to achieve more efficient and cost-effective large-scale production. For application innovation, special flexible components suitable for extreme environments will be developed, equipped with interactive functions such as smart dimming and health monitoring, along with establishing a sustainable material recycling system. This will drive the transformation of flexible photovoltaics from a single power generation function to an intelligent, scenario-based 'energy skin'.

-

0503-2025

Solar Roof Development: A Bright Future for Sustainable Energy

In recent years, the solar roof industry has witnessed remarkable growth, driven by advancements in technology, increasing environmental awareness, and supportive government policies. Solar roofs, which integrate photovoltaic (PV) panels into roofing materials, are revolutionizing the way we generate electricity while providing a sustainable solution to energy consumption.

-

3112-2024

Innovations and emerging trends in the photovoltaic materials market

What are photovoltaic materials? The materials used to produce solar panels or cells that convert sunlight into electricity are known as the photovoltaic materials market. These materials are primarily semiconductors that absorb light and convert it into electrical charges. Perovskite, organic and silicon-based photovoltaic materials are the most widely used types of photovoltaic materials. Silicon-based photovoltaic materials dominate due to their efficiency, reliability and proven production methods. However, new technologies such as perovskite solar cells are beginning to emerge as possible industry game-changers because they can deliver higher efficiencies at a cheaper cost. Traditional solar panels are not the only photovoltaic materials on the market. The uses of solar energy are also expanding thanks to advances in solar thin films, bifacial solar cells and building-integrated photovoltaics (BIPV).

-

1211-2024

How to deal with scrapped solar panels?

-

1810-2024

Photovoltaic development trends in 2024

-

1109-2024

The effect of Photovoltaic Welding Strips on Solar Module

Solar PV ribbon are an important part of every mainstream solar panel for interconnecting solar cells and providing connection with junction boxes The photovoltaic wire is a tin-plated copper strip with a width of 1-6mm and a thickness of 0.08-0.5 mm and a coating thickness of 10-30 μ m .

-

1707-2024

The solar flexible panels encapsulation film materials choose.

Lightweight photovoltaic transparent front plate encapsulated components Currently, the front plate materials of lightweight photovoltaic modules on the market mainly include soft glass, ETFE (ethylene-tetrafluoroethylene copolymer), PVDF materials, etc.

-

0507-2024

The development trends of solar film of POE、EPE、EVA、PVB

Currently, the photovoltaic solar module industry is undergoing a transition period from PERC technology to N-type technology. N-type cells represented by TOPcon have begun to enter the mass production stage of explosive growth. This transformation has put forward higher requirements for the performance of the encapsulation film of photovoltaic modules. Photovoltaic film encapsulation materials are used between the solar glass/backsheet and solar cells. Their main function is to protect the solar cells, ensure that the photovoltaic modules are not affected by the external environment during operation, and extend the service life of the modules.

-

1605-2024

The development trend of POE and its impact on the photovoltaic field.

POE has good elasticity, strength, aging resistance, weather resistance, and water-proof properties. Its traditional application areas are mainly in automotive parts. Photovoltaic-grade POE is mainly used for photovoltaic components, especially in the packaging of TOPCon, HJT, and perovskite.